Ladle is a basic equipment in metal production industry. In most of the cases this same solution will work perfectly over decades. However with over 20 years of experience in a metal industry we faced numerous cases where ladle required modifications, typical cases are:

-Required increased capacity,

-Increase of operational temeperature,

-Additional operations in ladle route.

With ladle even limited changes will impact surrounding equipment (cleaning station, preheater, etc) and operations. Beside pure update of Ladle design, NAVIC supports customers with identification of optimal changes, update of operational procedures and verification of impact changes.

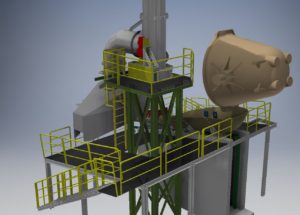

During a typical production cycle, ladle may go to several different places, such as:

-Preheater,

-Cleaning station,

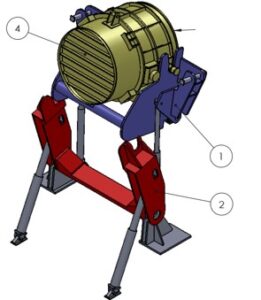

-Tilting chair,

-Sampling station,

-Ladle wagon.