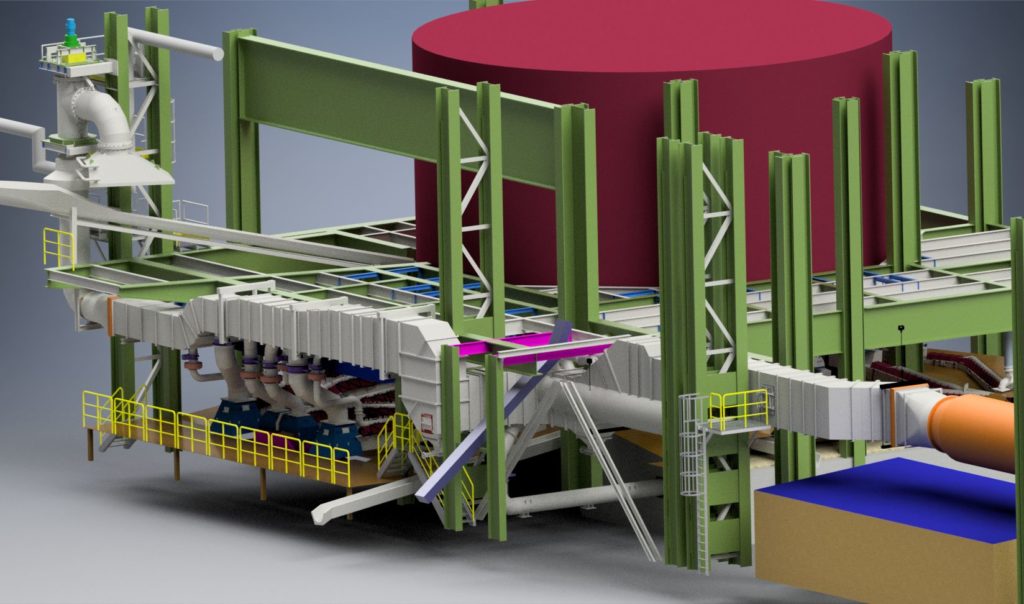

Installation of local ventilation of an electric furnace and installation of maintenance cranes

The task assigned to the NAVIC team was to design the ventilation and extraction of gas and fumes from the vicinity of the electric furnace. The need to modify the existing installation resulted from the intensification of the slag re-copping process in the electric furnace and the need to adapt to current technological and HSE requirements.

The main gas extraction units were designed for:

– Drainage baskets of the alloy 5 x ~11.780 m3/h/, at a temperature of ~350°C

– alloy drain gutters 5 x ~2,950 m3/h at ~350°C

– slag draining baskets 5 x ~6,000 m3/h/ basket, at ~250°C

– slag drain gutters 5 x ~8,840 m3/h at ~350°C

– a gutter basket for flooding of converter slag 1 x ~50,000 m3/h at ~90°C

– vats and hatches of the alloy drain vehicles 2 x ~20,000 m3/h at ~90°C

– a gutter for a passable alloy drain 1 x ~16,000 m3/h at ~90°C

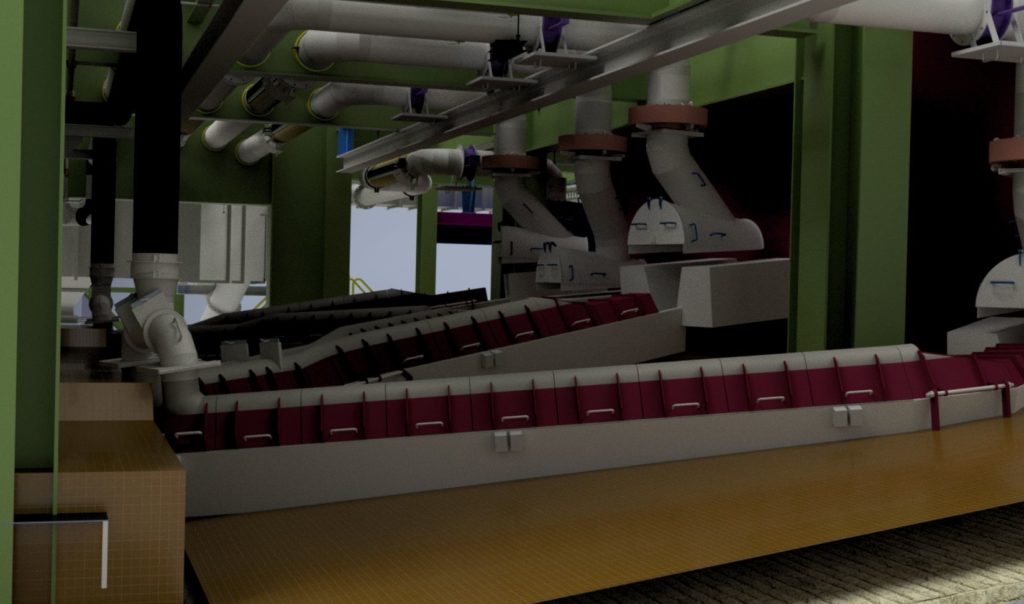

The designed installation includes: manual and hydraulically driven rotating hoods, fixed and removable hoods, drain channel covers with slot lashings open and removable, slot gates, spark and hot element catcher, fan and bag filter.

The total amount of extracted gases from the area of alloy drain, slag and pouring of converter slag is ~ 118.460 m3/h at ~106°C.

In order to facilitate the handling of the lashings over the gutters, the installation of maintenance cranes was designed.