Rebuilding of Building and Mineral Wool Production Line TRL03

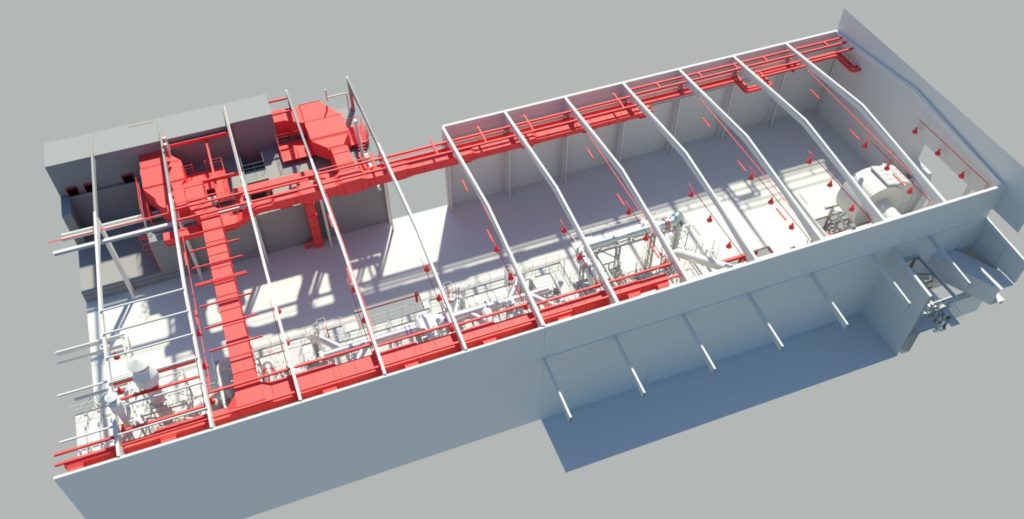

Replacement of the furnace and related production line together with modernization of technological pipelines – this was the aim of our new client’s investment task.

Our task was to develop a multi-discipline construction and executive design covering, among others:

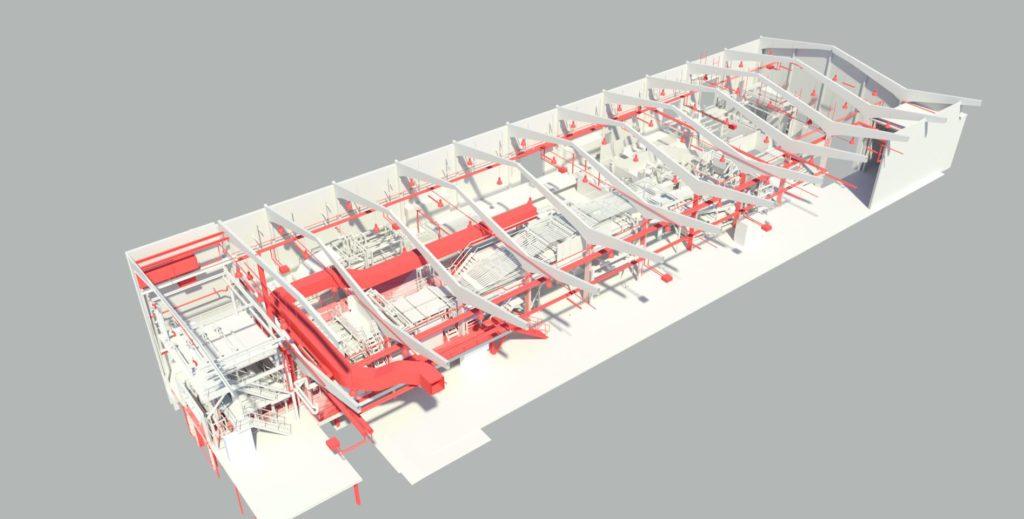

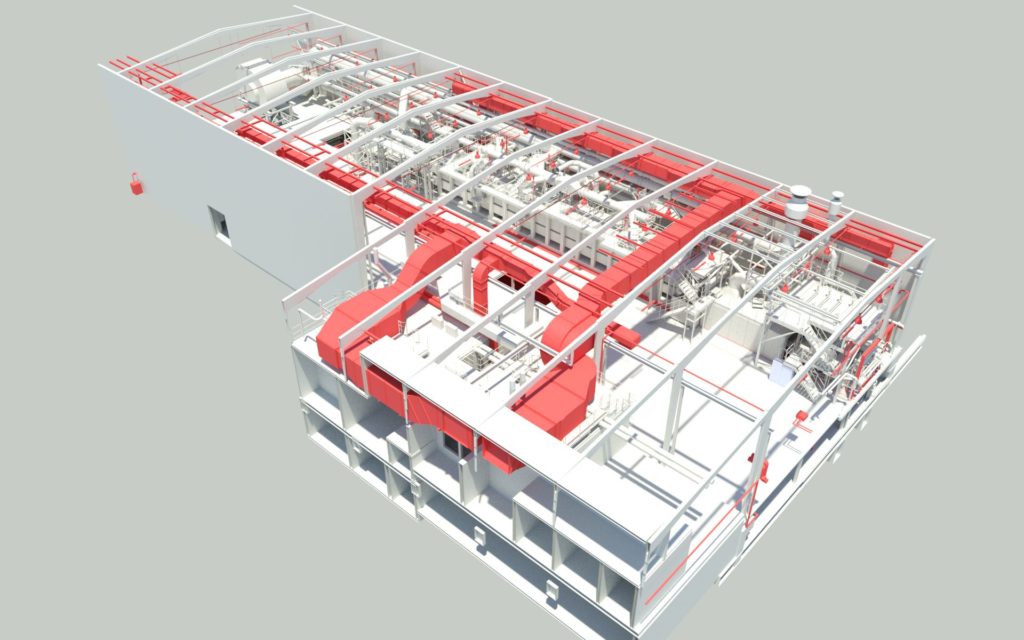

– reconstruction of the existing furnace building and production hall, including reinforcement of the supporting structure elements with foundations, new supporting structures of the furnace and production line, new foundations for equipment;

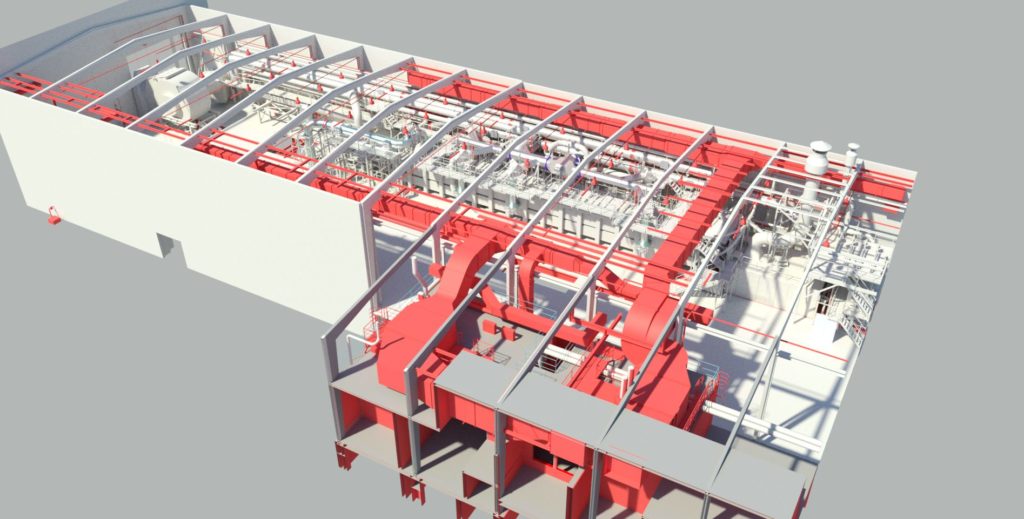

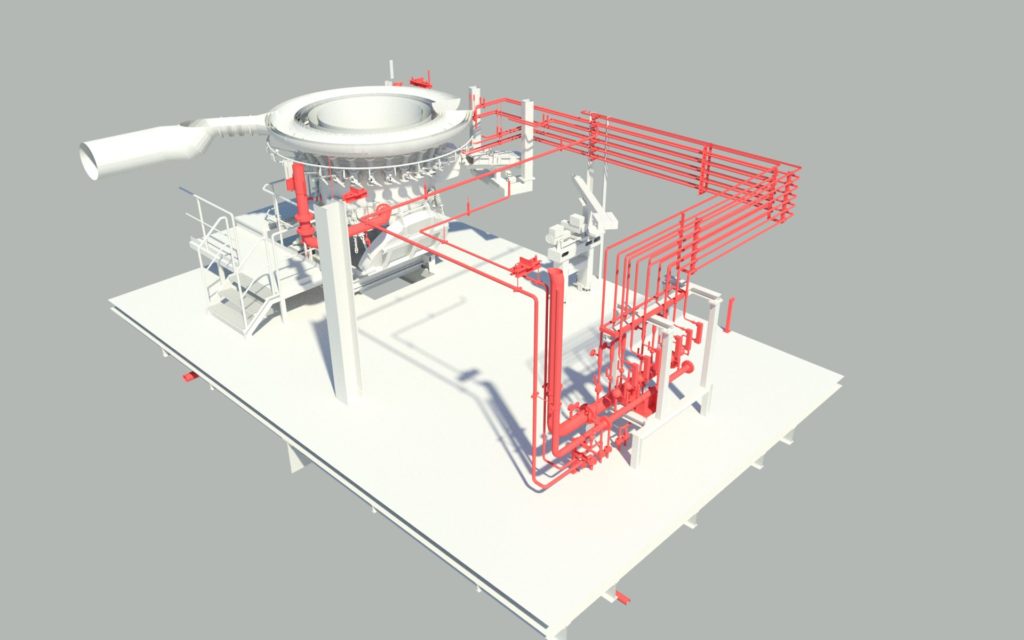

– modernisation of the installation of technological pipelines in the scope:

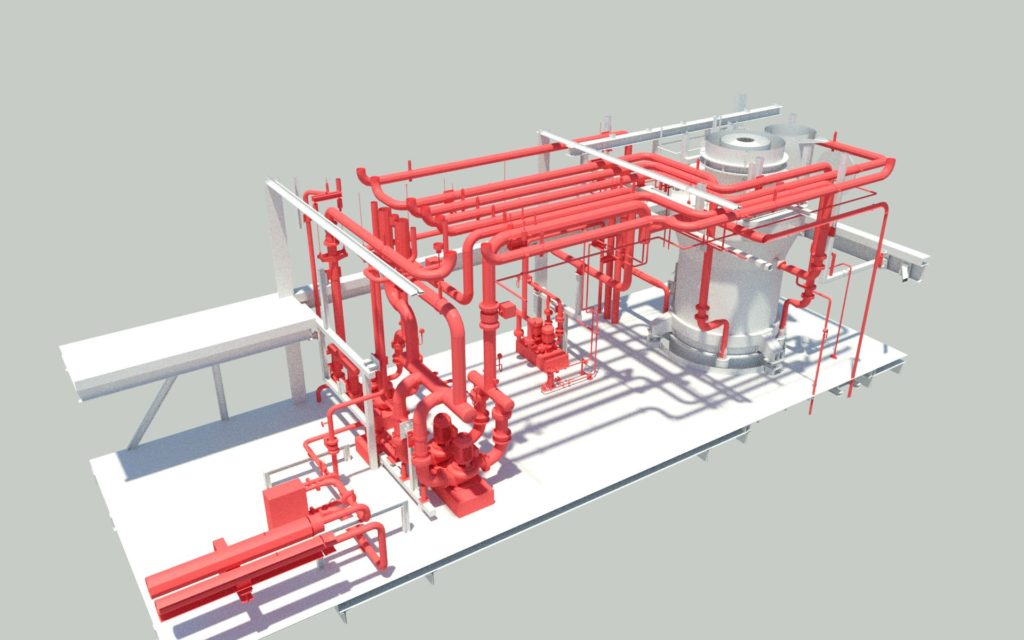

– design of pipelines for the furnace cooling circuit;

– design of heating pipelines for the heat exchanger circuit;

– design of compressed air pipelines;

– location of furnace cooling circuit pumps and heat exchanger in the modernized building;

– verification of the selection of pumps by the Customer;

– heating and ventilation of the production hall and furnace building together with heat recovery from the furnace cooling system;

– execution of the project using a point cloud;

– design using software: Autodesk Robot, RM WIN, Fd-Win, Bentley AutoPipe Autodesk Plant 3D, Autodesk Navisworks.

The project required work in an international environment, 3D model coordination both within newly designed objects and devices, and a highly built-up situation presented in 3D model in the form of a point cloud. Due to the location of the new technological line in the existing buildings, the project required extensive fire analyses together with allowing for deviations from the applicable regulations. Due to the residual archival documentation, the inventory of underground infrastructure and foundations was carried out using geo-radar measurements.

The project was completed within the assumed time frame, the new furnace and production line were put into operation, contributing to the improvement of production efficiency and the efficiency of the installation’s operation, at the same time providing much better environmental protection conditions.

45,000 t/year – production line efficiency

115,000 m3/h – ventilation capacity for the production hall

1,300 mb of technological pipelines

Będzie link do filmiku na youtube