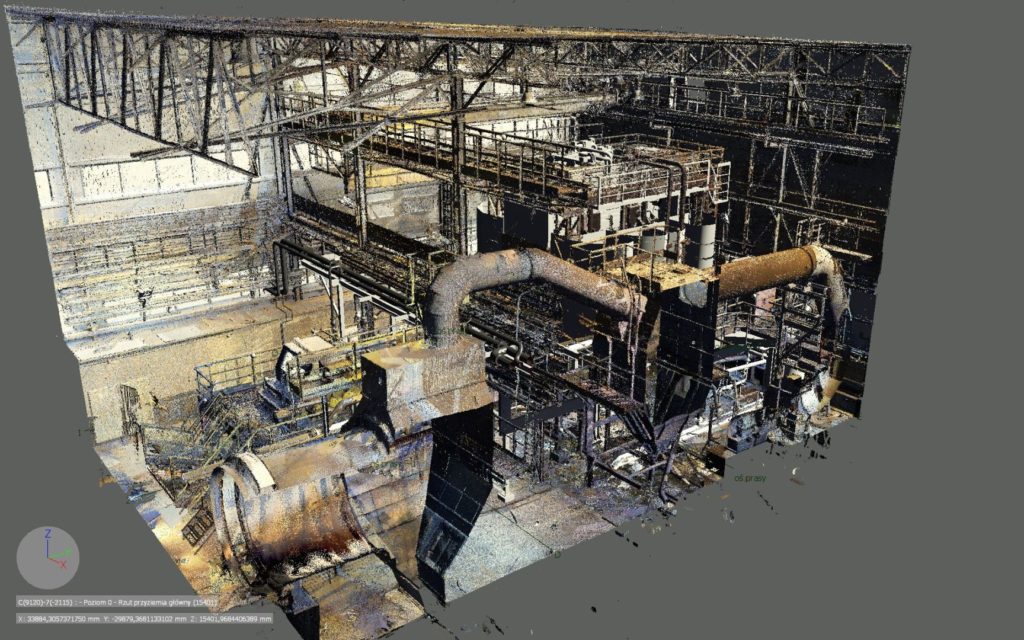

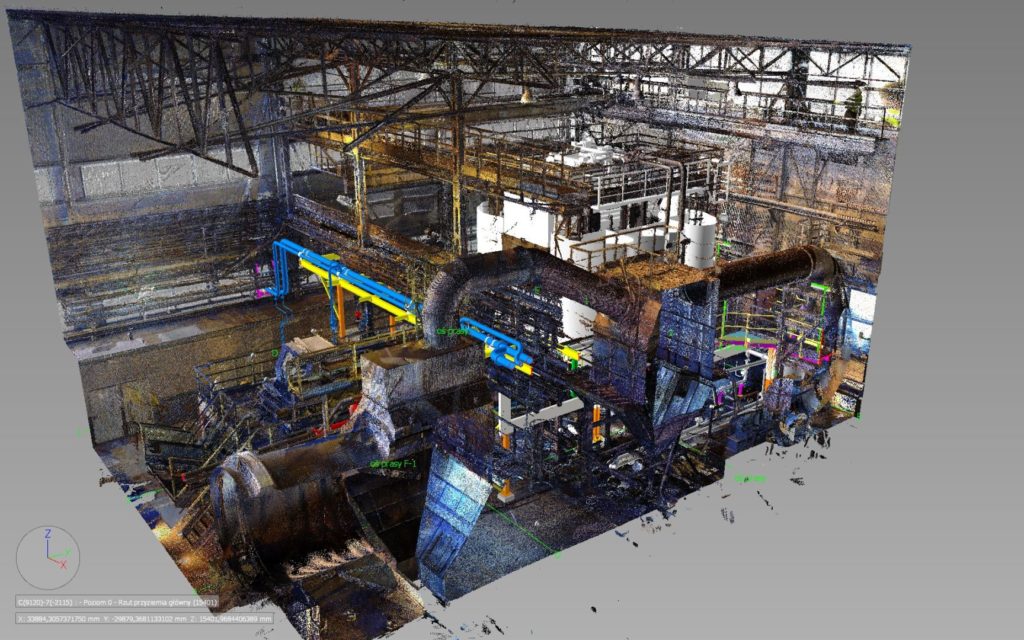

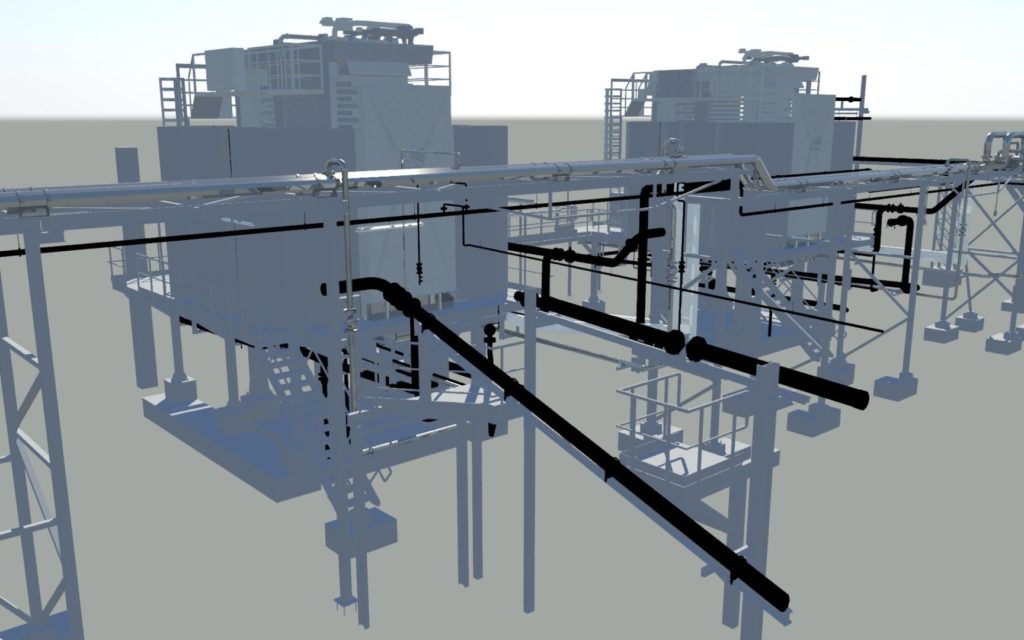

Installation of filter presses and construction of a compressor station building

The task assigned to the NAVIC team was to design the installation of 3 new filter presses. Due to the current wear and tear of existing filter presses, it was necessary to purchase new equipment with higher parameters of filter cake drying. As part of the project, a single system for drying the wet concentrate with compressed air pressure and drying had to be created. The investor assumed the implementation of the entire investment in several stages, which was taken into account in the design of new installations, structures and support systems while maintaining continuity of production and operation of existing installations.

The scope of design works performed by our team:

Technology and pipeline installations:

– Compressed air drying system for 5 filter presses working in a cyclic system with an average capacity of 236 m3/min FAD at a maximum pressure of 16 bar, with a total buffer air volume of 140m3;

– Compressed air pressure system for 5 filter presses working in a cyclic system with an average capacity of 37.8 m3/min FAD at a maximum pressure of 25bar, with a total buffer air volume of 22m3;

– AKPiA compressed air system for all newly designed filtration systems with a capacity of 138 m3/h at a maximum pressure of 10 bar;

– Filter fabric washing water system with a capacity of 18 m3/h at a maximum pressure of 15 bar;

– Concentrate feed installation with a capacity of 288 m3/h at a maximum pressure of 7 bar;

Construction industry:

– Foundations for new filter presses with filter support frames and service platforms;

– new control room as a control cabinet room for new filter presses;

– a compressor room building consisting of a compressor hall and buffer tanks designed in steel construction and a two-storey electrical and technical part designed in traditional (brick-reinforced concrete) technology;

– sub-constructions for pipelines, access points to measurement devices and foundations for accompanying devices;

Sanitary installations industry:

– in the new control room – air conditioning with heating function together with mechanical supply ventilation, drinking water installation together with sanitary sewage system;

– in the compressor room building – gravity and mechanical ventilation with electric heating, rainwater drainage from the roof and industrial sewage system inside the building;

Electrical industry:

– power supply installation of four filter presses of total power 615kW;

– lighting systems for the control room, filter presses and compressor room building;

– power supply installation for pumps with a total power of 875kW;

– power supply system for compressors with a total power of 1590kW;

– power supply installations for auxiliary equipment and cable routes;

Automation industry:

– pump control system;

– control system for pressure and drying air compressors;

– communication network system;

– control and measurement equipment installations.