Combustion system and flue gas extraction system for copper granulation furnace

The aim of the project was to solve the problems of the combustion system in the copper granulation installation. The problem of the excessive amount of sulphur fumes and flue gases escaping and the incomplete postcombustion of sulphur in the afterburner chamber was solved by designing the modernisation of the existing installation in the following scope:

– improvement of exhaust gas extraction from the furnace and afterburning chamber by replacing the exhaust fan: 11,500 m3/h at 1450Pa;

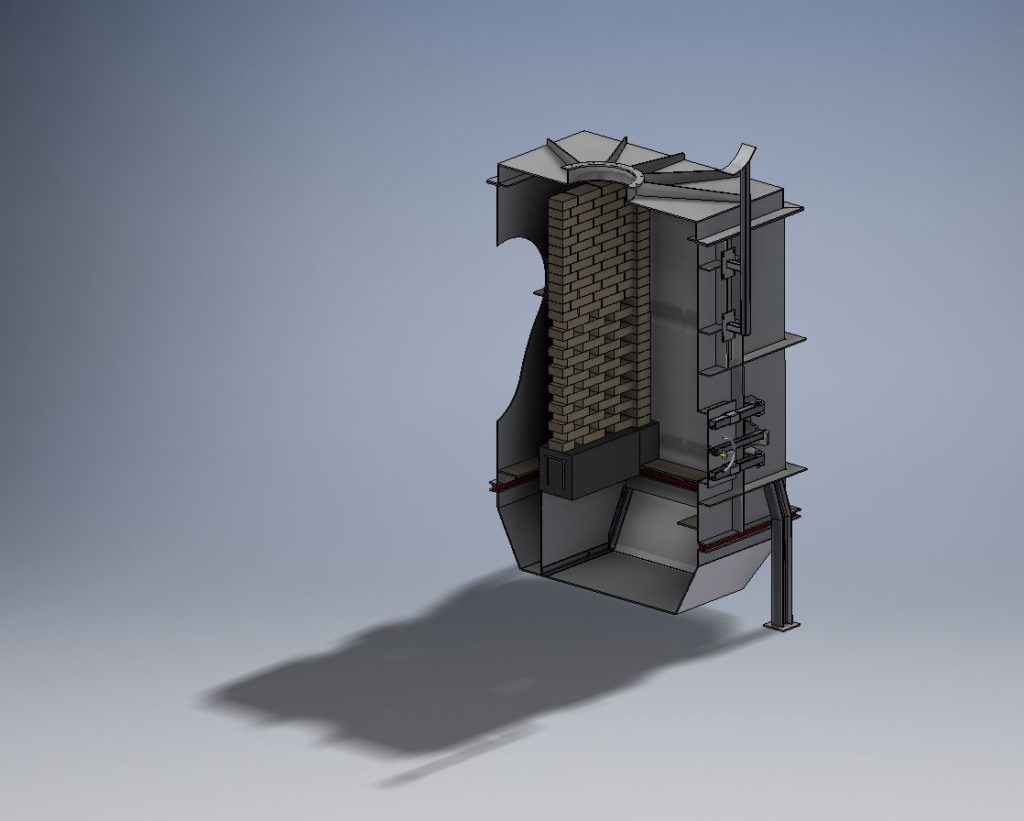

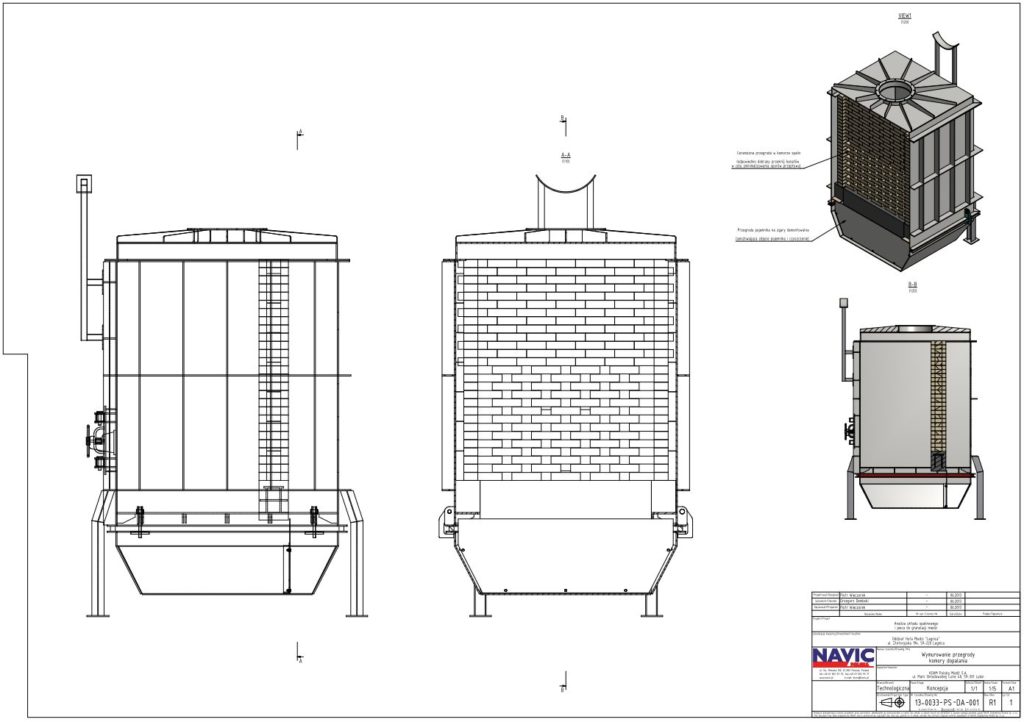

– improvement of the afterburning chamber through the installation of an additional partition with a change of the inlet nozzle (on the basis of flow calculations of exhaust gases from the furnace through the chamber to the chimney). Chamber capacity ~6.5 m3;

– changes in the flue gas discharge pipeline resulting in less overgrowing of the pipeline with sulphur combustion products, which reduced the corrosion problem of the pipeline and fittings;

– reconstruction of the combustion chamber with a partition and lining (based on necessary strength calculations).